Can Digital Twin Environments Help Train Robots More Effectively?

A MarketsandMarkets analysis projects that the growing need for AI-driven simulations and automation technologies will propel the digital twin market’s growth from $10.1 billion in 2023 to $73.5 billion by 2028. Digital twin environments have become a groundbreaking option as robotics businesses continue to look for new and creative ways to train and test their robots before deploying them in the real world.

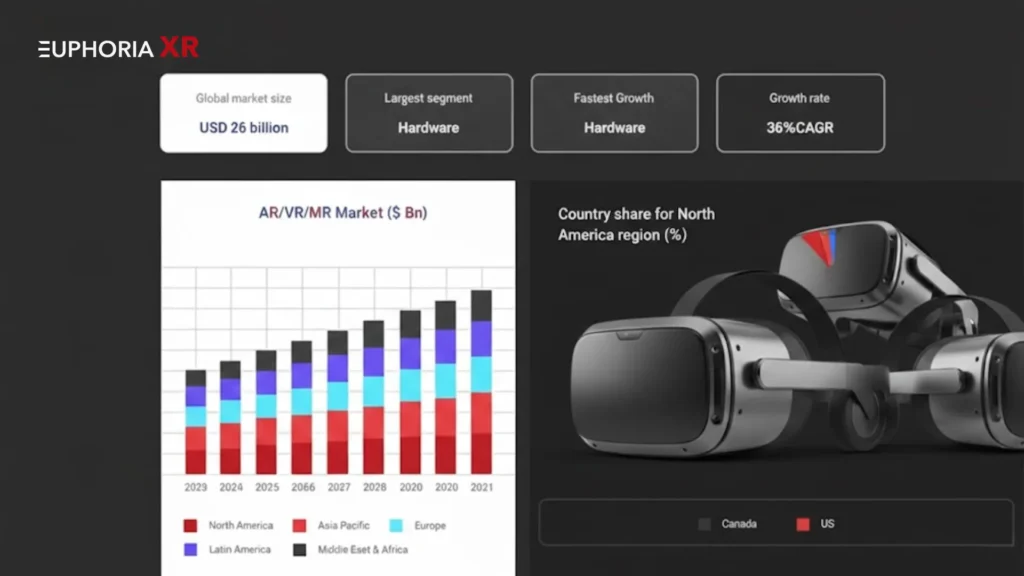

Robotic companies are searching for new and creative ways to train and test their robots before putting them in real-life situations in the fast-paced world of today. Using a digital twin environment—a virtual representation of the real world—to train robots safely and effectively is one of the best strategies. The potential of digital twin environments to produce sophisticated simulations that support robotic development and AI-driven research is already being investigated by businesses such as EuphoriaXR, a leading AI Development Company.

A recent study investigates how robots, 3D printing, artificial intelligence, digital twin environments, and storytelling are combined to produce immersive, interactive experiences called “story living.” Story living blurs the distinction between virtual and physical realities by enabling users to interact and participate with digital surroundings, in contrast to traditional tales where audiences passively absorb content.

Businesses may improve training, entertainment, and research applications by incorporating AI-driven simulations and digital twins to recreate real-world situations with remarkable accuracy. Because it allows robotics businesses to test, evaluate, and improve AI models in a realistic virtual environment before implementing them in the actual world, this technology is especially pertinent to them.

Furthermore, robots and 3D printing help to make computer simulations come to life, bridging the gap between virtual prototypes and practical implementations. In addition to influencing robotics research, this study demonstrates how AI-Powered Digital Twins are revolutionizing fields like education, healthcare, and entertainment, where real-time interaction with digital duplicates can improve user engagement, learning, and diagnosis.

Digital Twin Technology: What Is It?

A high-fidelity virtual model that mimics real-world systems, surroundings, and objects is called digital twin technology. Without the dangers and expenses of real-world experimentation, it offers robotics researchers a safe and immersive environment to test algorithms, improve control schemes, and gather performance data.

A popular tool for creating digital twin simulations for robotic training is Unity, a potent real-time 3D development environment. Engineers may construct realistic settings that closely resemble real-world situations using Unity, whether they are creating interactive theme park droids, industrial robots, or autonomous automobiles

The Robotics Secret Weapon? A Digital Twin Environment.

AI-Powered Industrial Metaverse: Robotics Training’s Next Development

The training, testing, and deployment of robots are being reformed by the idea of an AI-powered industrial metaverse. Leading robotics businesses are combining digital twin environments with the industrial metaverse to replicate real-world situations with remarkable accuracy, according to the MIT Technology Review. This method drastically lowers costs and minimizes dangers in the real world by allowing AI-powered robots to go through a rigorous virtual training process before working in real-world settings.

Digital twin technology is being actively used by IT giants like Foxconn and Nvidia to develop complex manufacturing simulations. With the help of Nvidia Omniverse, Foxconn’s digital twin technology allows for the real-time simulation of manufacturing floors, maximizing robotic automation, artificial intelligence, and predictive maintenance before actual deployment.

How Digital Twin Environments Can Be Used by Robotics Companies

1. AI-Driven Education for Intelligent Robots

Assuring adaptability to uncertain surroundings is a significant difficulty in robotics training. With the help of AI-driven feedback loops offered by digital twin simulations, robots can refine their skills through millions of simulated encounters before stepping into the real world. Digital twins are being used by companies like Siemens and Motoman to minimize training time and optimize robotic motion planning.

2. Predictive maintenance combined with industrial automation

Digital twins improve industrial automation by facilitating predictive analytics, according to a paper from Digital Engineering 24/7. By keeping an eye on robot wear and tear, businesses can make sure maintenance is done before problems arise. This technology increases productivity, decreases downtime, and enhances supply chain efficiency.

3. Smart Factories with Advanced Robotics

Industrial robotics is moving toward completely autonomous manufacturing facilities, where AI-powered robots function in digital twin settings, claims Automate.org. Without interfering with actual production, engineers may evaluate robotic behaviors, duplicate intricate assembly lines, and improve automation techniques using these simulations.

4. Training and simulating realistic robots

Real-world robot training presents difficulties like erratic conditions, exorbitant expenses, and possible harm. These issues are resolved by digital twin environments, which provide a risk-free environment for AI-driven simulations used to teach robots.

5. Learning and Adaptation Driven by AI

Massive volumes of data are necessary for AI-based robots to become more adaptive and make better decisions. Before incorporating AI models into practical applications, researchers can use digital twins to perfect them over thousands of simulations. The learning process is greatly improved by this method, which increases robots’ proficiency in managing challenging tasks.

6. Improving Automation in Industry

Warehouse automation, shipping, and manufacturing all heavily rely on industrial robots. Digital twin simulations are used by robotic companies to optimize robotic performance and guarantee seamless operations in automated manufacturing. Businesses can increase productivity and decrease downtime by virtually simulating production lines and supply chain operations.

Applications of Digital Twins in Entertainment and Theme Parks

The transition to AI-enhanced theme park experiences is exemplified by Disney’s Droidsmith Otto and BDX droids. Before interacting with guests, these interactive robots undergo extensive testing in virtual environments thanks to digital twin simulations. For AI-driven entertainment, the capacity to anticipate real-world interactions enhances safety, responsiveness, and engagement.

The Two Main Participants in the Creation of Digital Twins: Unity and Nvidia Omniverse

Two of the best tools for producing photorealistic digital twin settings are Unity and Nvidia Omniverse. While Nvidia Omniverse concentrates on real-time collaboration and industrial-scale virtual manufacturing, Unity is frequently used for robotics simulations, AI modeling, and automation testing. With the aid of these resources, robotics engineers can:

Model intricate industrial procedures

Maximize automation driven by AI

Incorporate motion planning for robotics based on physics.

Robotics’s Prospects for Digital Twin Environments

Digital twin environments will become more and more important in research and development as robotics businesses continue to push the envelope of innovation. The distance between virtual training and real-world deployment is gradually narrowing because of companies that are leading the way in next-generation simulations.

The future of robotics is being shaped by digital twins, which will provide smarter, safer, and more efficient robots in everything from production automation to AI-powered theme park droids. Integrating a digital twin environment into your workflow could be the secret to unlocking the next major discovery, regardless of whether you are a robotics engineer, AI researcher, or company trying to maximize automation.

Why Choose EuphoriaXR for AI Development and Consulting Services?

EuphoriaXR offers AI solutions designed for companies looking to improve their R&D procedures. Large language models (LLM), computer vision, deep learning, statistical analysis, rapid engineering, AI model creation, AI consultancy, AI algorithm development, AI support and maintenance, and AI-powered automation are among their areas of expertise. These services give companies the ability to incorporate AI-powered solutions into digital twin, automation, and robotics settings.

EuphoriaXR provides useful and scalable solutions for businesses seeking personalized AI-driven simulations or robotics training environments that boost productivity and creativity. Visit EuphoriaXR to find out more about their AI development and consulting services.

Wrapping Up!

Digital twin technology is revolutionizing research, development, and deployment as industries continue to include robotics and artificial intelligence. Digital twins offer an economical, scalable, and extremely successful method of training and improving robotic systems, from improving AI-powered learning to optimizing industrial automation. Businesses that make investments in AI-powered simulations are putting themselves at the forefront of technological development, guaranteeing increased precision, effectiveness, and flexibility. Businesses can remain ahead of the competition in the robotics and automation space and speed up their innovation cycles by utilizing platforms like Unity and working with seasoned AI solution providers.